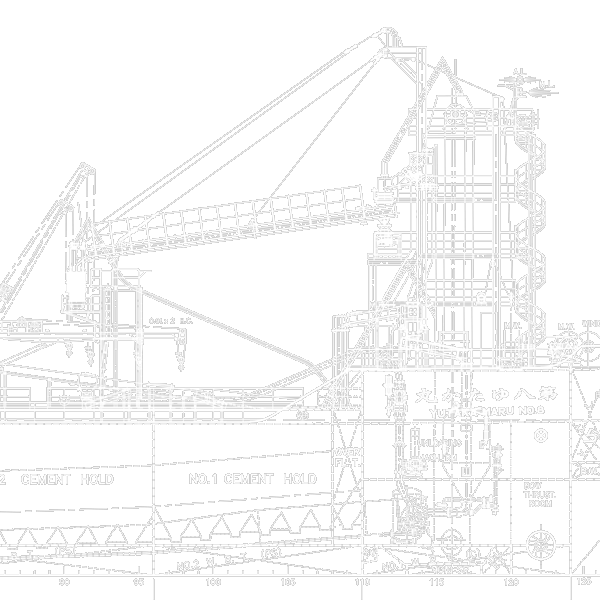

m.v. YUTAKA MARU NO.8

4,300TDW CEMENT CARRIER BUILT 2013

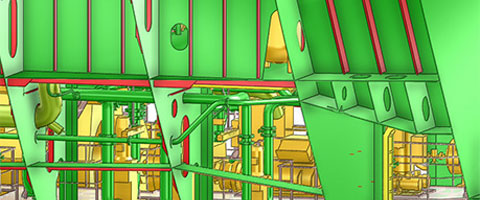

MODERN LABOR-SAVING CEMENT CARRIER WITH HYBRID CARGO HANDLING SYSTEM

Being the first cement carrier built by Kyokuyo Shipyard Corporation in about 10 years since the 7,000 tonner KUROHIME MARU born in 2003, YUTAKA MARU No.8 is a modern ship equipped with both mechanical and pneumatic systems for unloading while loading is done by a mechanical system.

As a state-of-the-art cement tanker, YUTAKA MARU No.8 is equipped with a variety of unique, high-tech features which include :

- Hybrid cargo handling system comprising 1,000tph mechanical loading, 600tph mechanical discharging and 400tph pneumatic discharging systems

- A bow thruster, a schilling rudder and slipping clutch system ensuring excellent maneuverability in port and narrow waters

- Energy-saving fins for better propulsion efficiency

- Air compressor (for cargo discharging) and shaft-generator driven by power taken off from the front-end of main engine

- Speed-up gearbox with omega clutch allowing to run main generators and shaft generator continuously in parallel, irrespective of the main engine's revolution state

- One-man bridge type console, electronic navigation chart display, GPS and 23" monitor radar being fitted on the bridge

- Integrated cargo and machinery monitor/controller in the engine room

- Equipment based on unmanned (M0) standard for crew's burden reduction and safer navigation

- Multiple cameras/monitors for remote monitoring

and many more, all reflecting the feedbacks and requests from the owner and superintendents.

LEADING PATICULARS

- 4,300tdw Coastal Cement Carrier

- NK NS*(CS) MNS* M0 n.f.

- Navigation Area:Coastal(Non-International)

- LOA x BM x DM : 97.03 x 16.0 x 7.1m

- Hybrid Cargo Handling SYstem - [Loading] Mechanical 1000T / [Discharging] Mechanical 600T + Pneumatic 400T Point

- Excellent Maneuverability with Schilling Rudder, Bow Thrushter etc. Point

- Generators Can Run Continuously in Parallel, Irrespective of the Main Engine's Revolution State Point

- Energy Saving Fins for Better Propulsion Efficiency

- One-man Bridge Console

- Equipment Based on Unmanned (M0) Standard Point

- Akasaka A38SR x 1 - 3,000ps MCO

- Service Speed About 12.5Knots

- Completed in March 2013

PHOTO GALLERY

FEATURED CEMENT CARRIERS

CEMENT CARRIER NEWS

Builder of Advanced Merchant Ships

KYOKUYO SHIPYARD CORPORATION

8-7, Chofu Minatomachi, Shimonoseki, 752-0953 Yamaguchi, Japan

© 2002-2026, Kyokuyo Shipyard Corporation