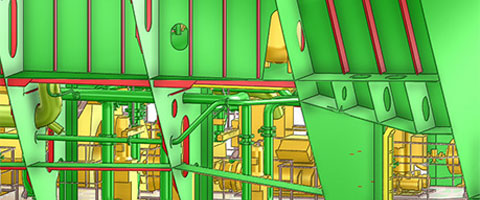

CONTAINER CARRIER

Introducing Kyokuyo's container carriers - our flagship product line.

THE STANDARD FEEDER. KYOKUYO'S JAPANMAX.

The recent history of maritime transport is also the history of containerization. Although the 20-foot marine container standard was established only in 1968, many cargoes are now transported in containers to every corner of the world. It is hard to imagine the world of seaborne trade without containers today.

More, faster, safer and cheaper - in response to the ever-increasing demands of the owners and operators, Kyokuyo has constantly been applying advanced technologies to brush up the "3S" /SPEED-STORAGE-STRENGTH/, thereby establishing itself as a container ship builder with an international reputation.

Our flagship product is JAPANMAX - a container feeder with a gross tonnage of less than 10,000.

Thanks to the great trust and support from customers in Japan, China, Korea, Singapore, Taiwan, and other Asian countries, Kyokuyo's JAPANMAX has established a firm position as a container feeder from hub ports to regional ports or between regional ports in Asia.

Since 2000, approximately one out of every three vessels have been of this type of container carrier. We are proud to say that our products support seaborne logistics in Asia - especially in East Asia.

A SOLID TRACK RECORD EARNED THROUGH CONTINUOUS INNOVATIONS

Our first Japanmax vessel was a 764TEU model built in 1996 for COSCO. Since then, thanks to the continuous efforts of our design team, improvements have been made in all directions, including the conflicting areas of cargo capacity and energy efficiency, while keeping overall length, gross tonnage, and other dimensions largely the same.

During this time, we have also incorporated valuable advice and feedback from the customers into our products. Non-sequential hatch covers; sophisticated tower bridge design that combines visibility and high load capacity; unique bow shape designed for operation in rough weather; the relentless pursuit of fuel efficiency; development of optimal hull structure; high-efficiency propeller; fins and propeller caps to optimize water flow; reefer container friendliness, etc. etc. Our accumulated know-how is unrivaled by our competitors.

In addition to complying with EEDI Phase 3 and other latest standards, we are constantly updating our products based on the needs of the times.

AND BEYOND THE STANDARD

And of course, we are not content with standard vessels alone, as we are good at one-off custom designs.

Let us give you an example. We are building a series of large-sized coastal container ships with an SSS-BOWed bridge for Imoto Lines. We have applied our extensive expertise in building ocean-going container carriers to this series, which is the largest Japanese coastal vessel ever built.

As the latest product to be built by Kyokuyo, the vessels feature, on top of our signature SSS-BOW, high-efficiency propellers, fuel-efficient paints, and a host of energy-saving and GHG-reducing technologies that set them apart from conventional coastal ships.

The first vessel, NATORI, with its bold and impressive design, was highly evaluated for its achievement of environmental load reduction in terms of both technological innovation and transportation efficiency. She was awarded the JAPAN SHIP OF THE YEAR 2015 "Small Cargo Ship Category Award" as well as the Japan Logistics Environment Award's "Award for Development of Technology that Reduces the Environmental Impact for Logistic Operations."

KEY POINTS

- Max Capacity About 1,100TEU (Gearless)

- Gearless or Geared

- Our Flagship Product that Supports Seaborne Container Trade in East Asia

- Rich Building Experience

- Unrivaled Know-how Accumulated Through Building Experiences for Many Major Operators

- Ask for Specifications Details and Customization

STATISTICS

Statistics for container ships built by Kyokuyo Shipyard since 1984. Please note that they may not be accurate in nature.

FEATURED CONTAINER CARRIERS

CONTAINER SHIP NEWS

Builder of Advanced Merchant Ships

KYOKUYO SHIPYARD CORPORATION

8-7, Chofu Minatomachi, Shimonoseki, 752-0953 Yamaguchi, Japan

© 2002-2026, Kyokuyo Shipyard Corporation