NEWS 062 : FIELD TEST PASSED. (AS EXPECTED.)

Every year, about 30 typhoons are born in the Northwest Pacific. Their route varies : some head to China, others proceed to Korean Peninsula, and several hit Japan also. The activity peaks in late summer when water temperatures are warmest. The intensity and thus impact of typhoons are increasing recently, probably due to raise of sea surface temperature caused by global warming. Whatever is the reason, typhoon measures are one of key issues every Far-Eastern shipyard is facing.

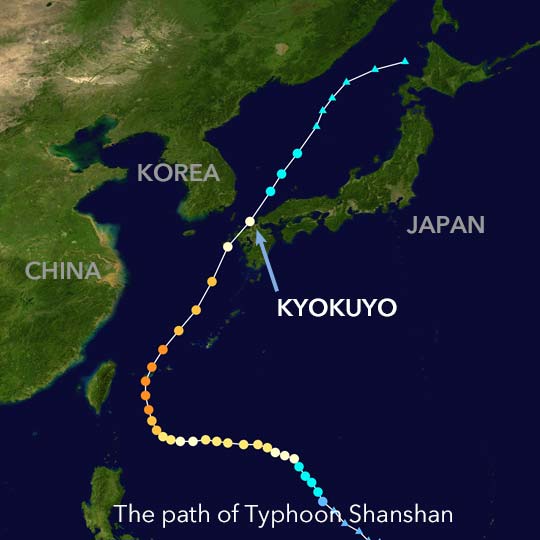

On September 17, as the night went on, our anxiety became somewhat strong because an extraordinary typhoon called Shanshan was again approaching Shimonoseki. Shanshan, aka Luis, was said to be the most dangerous typhoon since 15 years, with stunning intensity of 930hPa and 100-knots max sustained winds at time of landing at Sasebo. The super cyclone was heading straight toward Western Japan without losing its power, and Shimonoseki was expected to enter its storm zone (winds more than 55-knots) at 20:00 - exactly the time of high tide. Yes, It was the worst imaginable scenario. Much worse than the case of Typhoon Songda, which had made us decide to build an in-house power plant and carry out prevention works.

As we reported, we had strengthened our measures against storms. The countermeasures we had implemented include :

- In-house co-generation plant that allows us to control dock water level in case of power failure ;

- Extra steel walls of 70cm height surrounding the dock to protect the vessel from flooding water,

- Emergency rubber-packed water-tight doors at our 2 main gates ; and

- Concrete high-fence to prevent flooding water from coming into our premises.

For the office building safety, we had also placed 3 water-stopping gates around it. This way, we were protected more than quadruply, and we were certain that our damages, if any, would be minimum, although our new system was not tested in REAL conditions yet.

At 20:00, unusual storm turbocharged by high tide attacked Shimonoseki, and disaster was repeated - but only OUTSIDE of our premises for this time. The roads and parking area around Kyokuyo - everywhere outside Kyokuyo in other words - went all submerged 4-50cm below water level. Unlike the previous case, however, the sea-water routes from the roads to our premises were completely shut off by the aforesaid doors and fences. Inside the doors, storm waves were attacking directly from the sea, but water-stopping gates worked efficiently to protect our office buildings which has remained intact. Also intact was our new all-weather blasting factory, which functioned as safe shelter for some important equipments.

Obviously, we could not be completely damage-free : the typhoon broke part of gate at repair dock and some walls of machinery factory to name some examples. Our damages however turned out to be minimal and more importantly, within our expectations. Considering huge impact of Shanshan, which killed 11 Japanese and 2 Koreans, injured more than 200 people, caused a train derailment and destroyed cranes at other shipyard, we believe we are entitled to announce that our new investments passed those severe field tests with excellent results, as this disaster did not affect our ship building schedule at all. On 18th morning, we started our operation as usual business day.

[2006/10/28]